Contact UsCONTACT

Please feel free to contact us if you have any questions or concerns.

Inquiry FormStories

STORIES

SERIES EMBARK

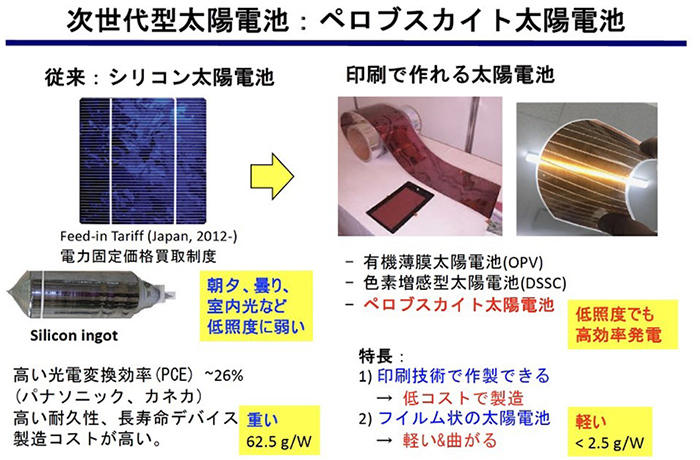

Next-generation perovskite solar cells, which enable higher conversion efficiency and lower manufacturing costs than the silicon-based solar cells currently widely available, are attracting attention from various perspectives, including energy, environment, and economy, as one of the candidates to play a leading role in next-generation energy.

EneCoat Technologies Co., Ltd. started full-scale operations at the end of 2018 with support from Kyoto University and Kyoto University Innovation Capital (Kyotoi-CAP), and as a frontline base in perovskite solar cell research and development, is aiming to implement various next-generation solar cells in society. We interviewed Atsushi Wakamiya, co-Founder, Chief Technology Officer (CTO) and Professor at the Institute for Chemical Research, Kyoto University, and Naoya Kato, co-Founder and CEO, about the company's current efforts. (Interviewer: Mae Kori)

I started my research on perovskite solar cells in 2013, and I think the timing was very good. I was one of the first to see the potential of this material, and I recruited volunteers from the JST PRESTO program to launch Japan's first perovskite solar cell research project. Subsequently, with the support of several government projects such as JST COI, JST ALCA, and the New Energy and Industrial Technology Development Organization (NEDO), we were able to work on the development and research of perovskite solar cells.

In addition, Kyoto University also started an on-campus grant program, the "Incubation Program," and we were selected for the first phase of this program, and established this company in January 2018. University researchers write papers and obtain patents, but that's often where it ends.... But my true desire has always been, "I want to somehow bring this wonderful technology to the world!" I have always wanted to "somehow get this wonderful technology out into the world! However, I don't have the funds, and it is difficult to do so as a university faculty member. However, I was offered full support, so I decided to start my own business! I decided to start my own business.

That's already the first step is to secure human resources. First of all, we had to ask ourselves, "Who is going to be the president? (laugh). The first person that came to mind was a classmate of mine from college, Mr. Kato. At the time, he was working in real estate in Takamatsu, and before that, he had built a career in real estate and turnaround-related work at investment banks in Japan and overseas, and was working hard as a businessman. He understood our technology, and we felt that we could not find a more reassuring ally in terms of management.

At first, as a friend, I thought what an interesting and unique thing he had to say (laughs). (Laughs) Although Mr. Wakamiya is a university professor, he has always had a strong desire to create his own company, or in other words, to commercialize, or at any rate, to bring his research to the world, and I was fascinated by that. I heard that the Kyoto University Group had established a scheme to provide full support, and I felt that this would be an interesting and rewarding opportunity. The deciding factors for me were, above all, the promising future of perovskite solar cells and the solid support system between industry, government, and academia. I felt that it would be a shame for a man not to take on such a dreamy research and development project with funding and support systems in place! (I made up my mind. (laugh) So I made up my mind to do it. I am still working hard as a single employee, but I have no regrets.

I was a little relieved to hear that (laughs). He managed to get the president of the company to accept the position, and everything was in place, but the rest of the process of securing human resources was really difficult. We had to meet and talk with many people, including mid-career hires, to get them to understand what we were doing. After that, some people joined the company, but of course there were people who were not suited to our work, so there were many twists and turns. But finally, we were able to recruit the right people, and we are now able to successfully manage the work.

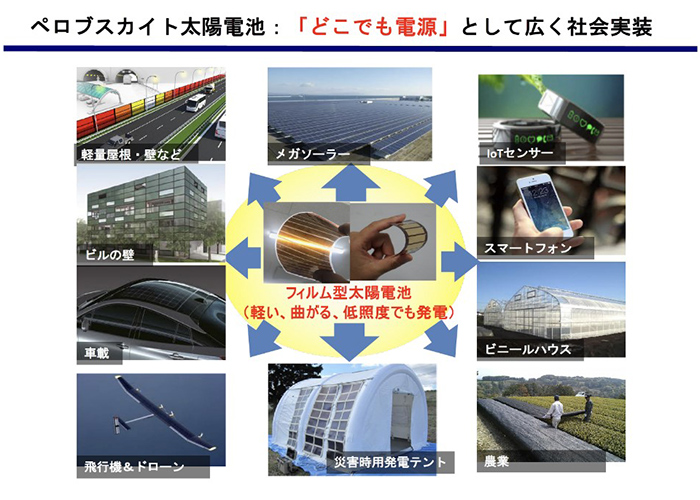

Simply put, the key word is "paintable solar cells. Currently, silicon-based solar cells are the mainstream, and large-scale mega solar cells are easy to recognize. Perovskite solar cells are made by applying a coating, so they are flimsy, lightweight, and bendable. Mega solar cells are heavy and require a large area of land, but if they are light and bendable, they can be used for attaching to building walls or curtains, for example. In addition, mega solar power generation requires high irradiance, which means strong light like sunny daytime, but perovskite solar cells can generate power even with low irradiance, which means weak light in the morning, evening, or on cloudy days. High-intensity light requires about 100,000 lux, but perovskite solar cells can generate electricity very efficiently even with very weak light, such as 1,000 lux or 200 lux. Therefore, I believe that perovskite solar cells can be applied to various devices in the future, such as power sources for IoT sensors. I call it a "power source for anywhere" instead of a "door for anywhere" (laughs).

For example, there is a material called amorphous silicon, which is used in power supplies for calculators and other devices, but our perovskite solar cells are known to be twice as efficient at generating electricity as amorphous silicon. Even with weak light, our perovskite solar cells can efficiently capture light energy and generate electricity, so I think there are endless opportunities for their use. For example, nowadays, each person carries around a variety of devices such as mobile PCs and smartphones. As devices become more and more sophisticated, they require more and more electricity. Carrying around a number of chargers is heavy and difficult, but perovskite solar cells are thin, lightweight, and convenient to carry, making them suitable for mobile batteries and the like.

From a sales perspective, we are aiming to expand our sales channels with lightweight, thin, and bendable as our biggest selling points. As I mentioned earlier, we believe that the product can be used for building walls and interiors, curtains and other fabrics, disaster tents that can generate their own electricity, and other applications such as airplanes, drones, agricultural greenhouses, IoT sensors, lightweight mega solar panels, space satellites, and many more. In fact, we are working on a joint development project with several manufacturers, and we are proud to say that this is truly a dream solar cell.

And the power generation film can be chopped off with scissors. If you design it well and put it on a wristwatch, you can make a cool wearable device (laughs).

Taking advantage of its ability to be freely cut into any shape, automobile manufacturers are currently conducting research on using it on the roofs and bodies of cars. It would be a dream come true to have a gasoline-free solar car that generates its own electricity without recharging while driving in the daytime. According to a demonstration experiment conducted in a certain prefecture, a solar car can run 35 km if it generates 1 kW of electricity. The average person uses a solar-powered car for about 25 km a day, which is enough to drive around Kyoto City.

We are also working with manufacturers to develop the latest 5G base stations. This base station is an aircraft that flies automatically and for long periods of time in the stratosphere, so it must be lightweight; one base station can cover a radius of 70 km, and it can use its own power generation even if the ground base station is damaged in a disaster or if there is a power outage.

Like the disaster tents I mentioned earlier, I think they will be useful in various fields of disaster preparedness. This is an area that we would like to actively promote in conjunction with industry, government, and academia.

I originally studied organic chemistry at university, and have been developing highly purified precursor materials for perovskite semiconductors from the viewpoint of materials chemistry and unique deposition methods using such materials by utilizing the expertise in synthetic organic chemistry, including material design, synthesis, analysis, and purification techniques I learned there. We have so far developed purified lead iodide (Pbl2), which is already commercially available and used in many fields. Subsequently, we have developed a new DMF complex as a second-generation, highly purified precursor material. It has a high purity of 99.998% and is fast and well soluble in solvents. We have further developed it and succeeded in developing a process that allows "slow" application to large-area films.

The ability to apply the coating slowly means that various coating methods are possible, and since large-area products can be produced, it is possible to develop a grand-scale application, such as covering an entire wall of a building with perovskite solar cells. Using this method, we are also aiming to develop a roll-to-roll coating technology for large areas in the future. At the same time, we intend to realize the mass production of perovskite solar cells and the social implementation of "power supply anywhere".

In fact, the Uji Campus established the Uji Area Incubation Support Office in October 2020. This is a project supported by Kyoto University to promote the practical application and commercialization of research results within the university. It develops and maintains the joint use of state-of-the-art equipment by multiple laboratories and strongly encourages the promotion of research and entrepreneurship in venture businesses. The greatest advantage of this project is that research and business can be conducted closely within the same university. Thanks to the latest equipment, we are able to make great strides in our daily research, and we can immediately discuss and start concrete matters on how to implement them without a sense of distance. In the future, interesting things may be born from the horizontal connections between laboratories.

I believe that perovskite batteries have the potential to solve the conflicting problems of energy and environmental conservation all at once. Our dream is to conduct research and development not only for the immediate future, but also for the next 100 or 200 years to ensure that our grandchildren and great-grandchildren will be able to live in a society that is useful to them. I would like young people to conduct research with this perspective in mind, and when in doubt, go back to the starting point of how the research you are doing now can benefit people and society. There are a variety of support measures available today to make this a reality, so I hope that you will gather information and seize the opportunity.

Unlike in the past, industry-government-academia collaboration has been realized in various forms, and giving concrete form to the results of university research is very realistic in this day and age. I myself jumped into the venture business world even though it was a gamble, and now I feel that it is truly rewarding and I am glad that I did. You can have practical experience in the field of business and management, and then use that career to become active in the world of research and development. I myself am a good example of this. People often say, "Give shape to your dreams," but you need funds to make it happen. Even though it is a high hurdle for an individual, now that the understanding of venture businesses has deepened and the circle of support has expanded, it is possible to make it a reality and not just a dream. I would like all young researchers to experience the joy of being able to contribute to society by linking their research to people's lives, rather than nurturing it only in the laboratory.

I call it "purpose-driven research," and as an R&D person, I urge you to have such a vision, to work on what needs to be done for the next generation, not just science for the generation we are living in.

(Interviewed in November 2020. Affiliations, positions, etc. are as of the time of the interview)

EneCoat Technologies Co., Ltd. is working on the practical application of perovskite solar cells, the next generation of thin solar cells. Perovskite solar cells, which are ultra-lightweight and can be processed into film form, can be installed on vertical or curved walls and maintain high conversion efficiency even under weak indoor light. Perovskite solar cells were invented in Japan, but competition for development is intensifying around the world, and we are looking for companies that can support EneCoat Technologies together with Kyoto-iCAP.

Osami Kono

EneCoat Technologies Co., Ltd. website

Please feel free to contact us if you have any questions or concerns.

Inquiry Form