Contact UsCONTACT

Please feel free to contact us if you have any questions or concerns.

Inquiry FormStories

STORIES

SERIES EMBARK

Catalysts" are substances that promote chemical reactions and are used in the manufacture of pharmaceuticals, foods, fertilizers, and all other chemical products. Rare metals are commonly used as catalysts for chemical reactions, but they carry risks such as resource constraints and environmental impact. TSK has developed a reaction control technology for iron catalysts, which had been considered difficult to use, and has made it possible to stably extract the desired reactivity. Son Eun-Cheol, CEO of TSK, and Masaharu Nakamura, director and professor at the International Research Center for Elements Science, Institute for Chemical Research, Kyoto University, are challenging the greening of the chemical industry by using iron-catalyzed organic synthetic reactions to improve the functionality of existing materials and to provide new materials that can only be synthesized with iron catalysts.

(Interviewer: Mizuho Takita)

I was doing research on organic synthesis at a graduate school in Korea, and at the time, many of the papers I referred to were written by Japanese researchers. So I wanted to continue my research at a higher level, so I went to study at Kyoto University. Dr. Nakamura took over as my advisor in January 2006, and we graduated in March, so we were only together for three months. I graduated in March, so we were together for only three months. However, I was impressed by his human charm and his excellent research, so I visited him often after I started working there.

That was when I was assigned to the Institute for Chemical Research at Kyoto University. Moving a chemistry laboratory is very difficult. There is a huge amount of chemical compounds. I had to split up with a small group of staff and students to clean up. Mr. Son was a third-year doctor and extremely busy, but he helped me all the way through without a single grimace. I thought he was an amazing person. That was the beginning, and although we were both busy with our work, we continued to communicate with each other.

After receiving my doctorate from Kyoto University, I worked at Sekisui Chemical for nearly 10 years developing materials for displays. I was unable to get to mass production, so I changed jobs at Samsung Display to change my environment. I had a house in Shiga, but I convinced my family to move to Korea. After retiring in 2019, I was working as a consultant for a chemical company when I was approached by Dr. Nakamura about implementing iron catalysts in society.

No, there is a big difference between dreams and reality (laughs). I couldn't judge for myself how feasible it was, so I talked about it with my colleagues who had joined the company when I was at Samsung Display. He expressed interest, saying, "There is a possibility that it could be used as a material for OLED. I thought, "If that's what a specialist says, then it could work. I also thought that because I had experience working on both sides of the business, on the side of making materials and on the side of using them, I might be able to turn iron catalyst technology into a business, so I thought I would give it a try! I thought, "Let's do it!

Rare metals are produced in a limited number of countries, have geopolitical and depletion risks, and environmental pollution during mining is also a problem. Moreover, they are expensive. In contrast, iron is a metal that exists in abundance on the earth, is inexpensive, and has low greenhouse gas emissions during production. If iron can be used as a catalyst, environmental impact can be reduced and costs can be cut. For manufacturers, another major advantage is the ability to respond to ESG and SDGs by replacing rare metal catalysts with iron catalysts.

When I was a student, I came across synthetic organic chemistry and thought it was amazing and interesting to be able to create something that had never existed in the world before! I thought, "This is amazing and interesting! As I continued my research, I began to think that I wanted to do research that would lead to the world, and I focused on metal catalysts. There was a lot of research on rare metal catalysts often used in chemical synthesis, but strangely enough, there were few reports on iron catalysts, the most familiar metal. This intrigued me and I began my research.

As I accumulated know-how through a series of experiments, I found that I could control iron-catalyzed reactions, and in about 2000, I was able to acquire a sense of controlling iron catalysts. I was also conducting joint research with private companies to achieve actual production of compounds using iron catalysts, but it tended to be short-term research. I thought that the only way to commercialize iron catalysts as a broad, long-lasting science and technology was to establish my own company. But I didn't know what to do to start a business. So I approached Mr. Sun, who had experience in corporate development. I was selected for the Kyoto University Incubation Program, which Mr. Son took the lead in applying for, and I decided to get serious about it. And in 2021, I established TSK. By the way, the company name comes from the initial letters of iron (T), catalyst (S), and chemistry (K).

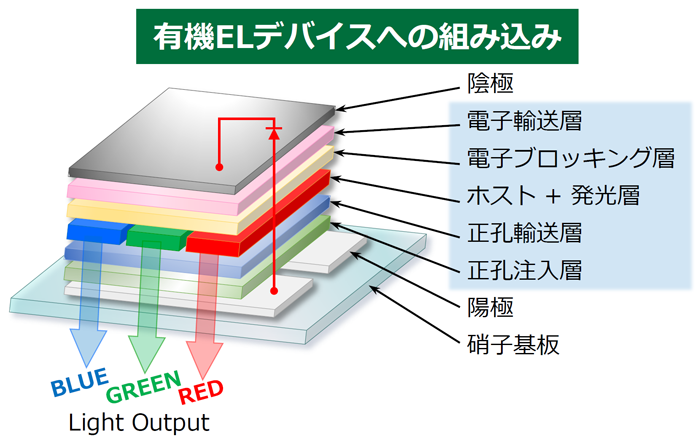

OLED materials are used in panels for monitors in smartphones, PCs, and TVs. We have been working with a major display manufacturer for a year and a half to improve the luminous efficiency and color purity of the material, with the aim of adopting it for 2026 model year products.

It is possible to replace the rare metal catalysts used in the synthesis of organic electronic materials with iron catalysts, and we have succeeded in creating materials with new performance that could not be achieved before using iron catalysts. If adopted, the impact would be significant.

Yes, we are looking for biostimulants. A biostimulant is an agricultural material that improves yield, quality, and storage after harvest by drawing out the inherent power of plants. They are different from fertilizers, which contain nutrients and compounds that help plants grow. This field is attracting worldwide attention from the perspective of addressing food problems caused by the world's growing population and increasing the efficiency of agriculture.

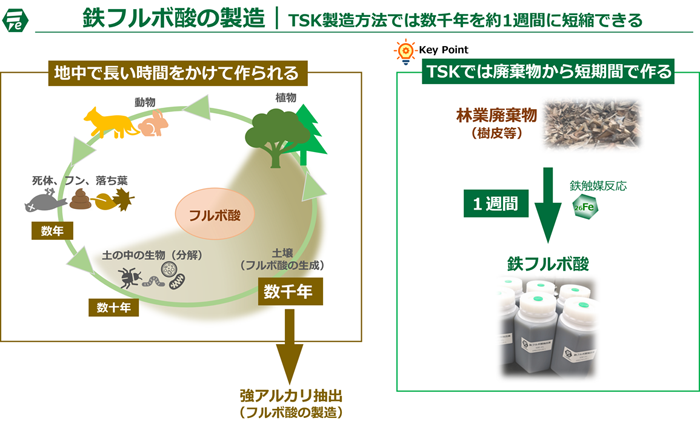

There are many types of biostimulants, including those using seaweed and microorganisms. What we are developing is humic substances. Fallen leaves and fallen trees gradually decay and turn into humic substances over a long period of time. We have found that this helps plants take in nutrients and iron. Humic acid, which is soluble in alkali and water, can be obtained from lignite and peat, but it requires too much time and labor, such as repeatedly digging up the ground. That is why we came up with the idea of using an iron catalyst to chemically transform the bark of trees discarded during lumbering into humic acid. With the cooperation of various companies, including a forestry company that provides the bark, a processing company that crushes the bark, and a manufacturing company that makes the humic acid, our original "Iron Fulvosan" was created.

In order to commercialize the product, we needed to evaluate it on an actual farm and build a factory capable of mass production, but we had no way to get there. However, a large-scale Korean farmer whom I met through an opportunity came to cooperate with us in a vegetable cultivation test, saying, "I will support you in the work that Mr. Sun is doing. As for production, the company we had asked for two years ago contacted us and said, "We are ready to start production. I decided on my own that we would sell the product in April 2025 when there was no prospect of commercialization at all, but I was surprised at how quickly things progressed once I set a goal.

Pharmaceuticals. I think the hurdles are high, but pharmaceutical companies are showing interest in iron catalyst technology, partly because the price of rare metals is rising. I believe there is a great opportunity.

We are considering the possibility of building a chemical industry that utilizes forest resources, like "Iron Fulvosan," which uses waste bark. Using cellulose from trees as a raw material to make various chemical products such as plastics and fuels will lead to the restoration of forestry, forests, and satoyama. I would like to create a "forest chemical industry" as a new chemical industry to replace the petrochemical industry. I want to take on various challenges, so when I have enough money, I would like to buy a forest!

Only if Kyoto-iCAP says yes (laughs).

I believe that if the world becomes friendly to all people and the environment, everyone will be able to live a safe and secure life. I hope that TSK's technology can be a catalyst for such a world.

As a manager, I have a lot of responsibility, but I find it interesting to be able to speedily do what I want to do at my own will. I don't have to write plans and reports every time I go on a business trip (laughs). I believe that Japan's chemical technology, which has been accumulated over many years, is of a high level and has the power to create new things. As a Kyoto University venture, I would like to create something new and introduce it to the world.

When I talked with Korean farmers and Kyoto forestry and lumber industry people, they got really excited about what they wanted to do next and what they could do. It was interesting to see the circle of excitement expand, even though we are from completely different industries. I don't think I would have had the opportunity to interact with people in the forestry industry if I had only been doing research. I think that starting my own business has broadened and deepened my contact with society. I am truly grateful for this.

I have always felt that I do not want to do the same things as others. It is with this in mind that I studied in Japan and established my company. I hope that you will consider your past experiences and what you want to do in the future, and take the plunge. And since starting a business is not something you can do alone, I think it is important to have a partner you can trust. If there is anyone who wants to start a business, I would be happy to discuss it with you personally.

Among the many possibilities for the future, find something you really want to do, and if it is entrepreneurship, do it without hesitation. You may not succeed right away, but if you keep at it, the experience will accumulate and take shape, so I think you should take on the challenge!

(Interviewed in May 2024. Affiliations, positions, etc. as of the time of the interview)

Due to increasing ESG considerations caused by soil contamination during mining of heavy precious metal catalysts, inexpensive and safe iron catalysts are attracting attention. However, iron catalysts have so far been limited to certain applications due to the need for large synthetic reactors with high pressure, and TSK is using the reaction control technology for iron catalysts developed by Professor Nakamura to develop new OLED materials, biostimulant materials, and other materials that can be used in industry. We hope that the activities of TSK and Kyoto University will contribute to the greening of the chemical industry.

Masayoshi Ohbayashi

TSK Corporation

Please feel free to contact us if you have any questions or concerns.

Inquiry Form