Contact UsCONTACT

Please feel free to contact us if you have any questions or concerns.

Inquiry FormStories

STORIES

SERIES EMBARK

With the spread of mobile devices and electric vehicles (EVs) and the expansion of data centers where data processing equipment is located, countermeasures against heat generated by electronic devices have become a major issue. Heat generation is a serious problem for electronic equipment, leading to malfunctions, deterioration, and ignition accidents. Currently, various cooling systems are used to dissipate heat, but their power consumption is increasing and their environmental impact is becoming an issue. U-MAP, a startup born out of a Nagoya University laboratory, has developed a new material called "Thermalnite" that solves this heat problem. Kenji Nishitani, president of U-MAP, is using this material as a weapon to try to solve the world's thermal problems.

(Interviewer: Mizuho Takita)

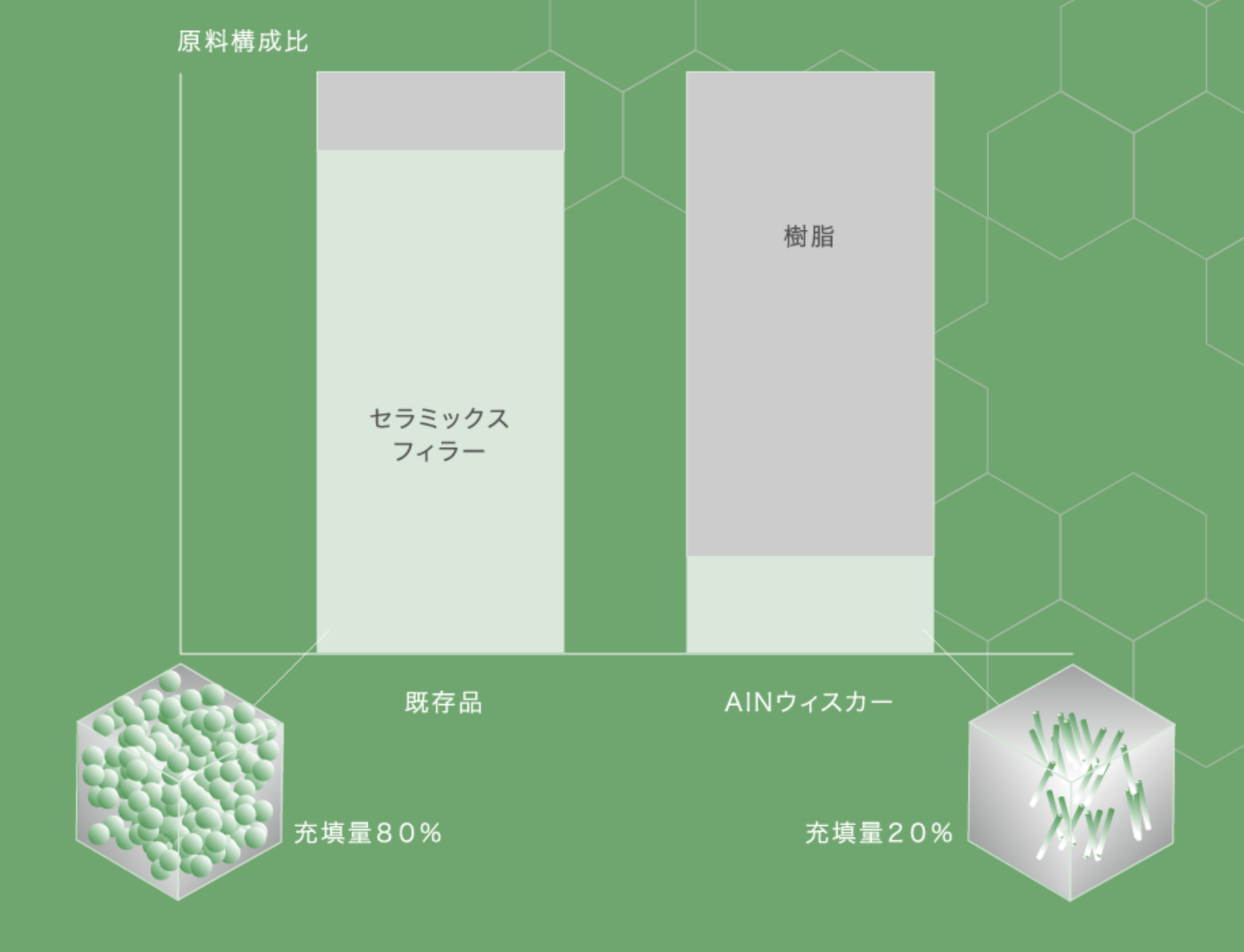

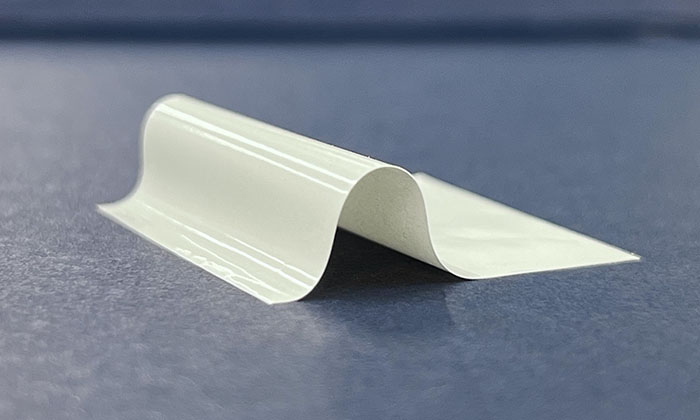

Electronic devices such as PCs and smartphones generate heat, and it is important to dissipate heat efficiently because such heat can reduce the performance, longevity, and safety of the devices. There are various ways to dissipate heat, and we are working to improve the effectiveness of heat dissipation through the materials used in our components. "Thermalnite" developed by our company is a compound of nitrogen and aluminum in fiber form. When added to component materials such as ceramics and resins, it quickly dissipates heat. Aluminum nitride itself is attracting attention as a material that conducts only heat without conducting electricity. Powdered materials have long been used as additives for ceramics and resin materials, but they cannot increase thermal conductivity unless more than 80% of the material is mixed. Thermalnite, however, requires only about 20% of the component material to increase thermal conductivity. This is because it is in the form of a fiber, which creates a network that allows heat to escape. In addition to its high thermal conductivity, Thermalnite can also increase the strength of components.

Currently, our business is the manufacture and sale of Thermalnite, ceramic substrates with Thermalnite added, and resin sheets.

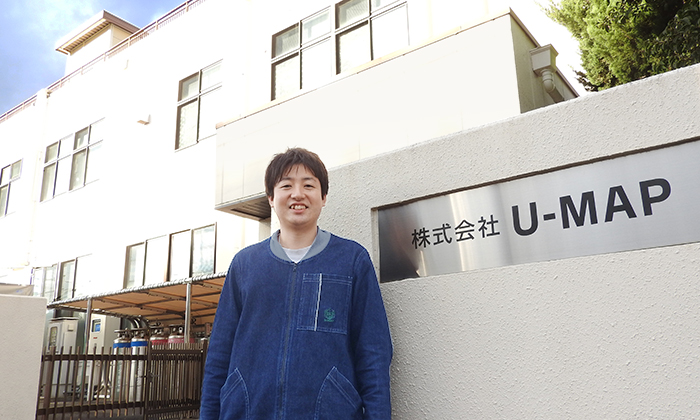

Thermalnite was founded in 2016 by Toru Ujihara, Professor at Nagoya University (Director and CTO) and Takahiro Maeda, Director and COO, who had worked for a semiconductor-related equipment company. Thermalnite's research and development began when I was working on semiconductor materials in Ujihara's lab and happened to come across a fiber-like aluminum nitride single crystal. The president of the company Maeda works for strongly encouraged us to start our own business together.

I was a member of Ujihara's lab at Nagoya University, and because I was interested in marketing and planning, I worked for a major regional supermarket after graduation. 3 years later, Dr. Ujihara asked me, "I'm starting a fun business, want to come? I said, "If it's fun, I'll go! I decided rather easily (laughs). (Laughs.) Dr. Ujihara's invitation may have been influenced by the fact that I often organized events and workshops at his laboratory. I also felt comfortable jumping in because Dr. Ujihara is the kind of person who always follows through when he decides to do something. The people at the company I was working for were also very willing to send me off, saying, "You don't get that kind of opportunity very often.

No, I did research on solar cell materials when I was a student, so I did not know much about these materials. At the time, I joined the company because I was intrigued by the fact that it was a company that was working to implement materials created through new technologies in society.

We are in the process of selling samples of Thermalnite. We were constantly attacking material manufacturers. The response from companies was very positive, and we were able to get a good response; we met with about 100 companies, and 40 of them bought samples. We realized that thermal countermeasures were such a big issue for companies.

Yes, I have heard that it was named after "Ultimate Material Processing". I heard that they named it "Ultimate Material Processing," but there is a rumor that it was originally "Ujihara Maeda Paradise" (laugh).

Fundraising. We needed a huge amount of funds to proceed with capital investment and R&D, but we were faced with difficulties unique to a materials manufacturer. It takes time for a materials manufacturer to get its business off the ground, so there are few investors who are interested. It seems that many materials-related start-ups have failed in the past. Also, materials are upstream of manufacturing. Even if a parts manufacturer wants to use this material, it is not certain that the company that manufactures the assembly or final product beyond that will be OK with it. It is difficult to see if there are companies that will really buy it.

This financing has allowed us to make capital investments. A large furnace has been installed at the plant and Thermalnite is now ready for mass production; one unit will be put into operation in January 2024, increasing to three units by 2026.

In terms of customer development, we not only manufacture Thermalnite itself, but also ceramic substrates and sheets, and we have made a conscious effort to appeal directly to electrical appliance manufacturers with thermal problems by making ceramic substrates and resin sheets using Thermalnite and showing their high heat dissipation effect and strength with data and proposing their potential. In November 2024, we started mass production of ceramic substrates through a capital and business alliance with Okamoto Glass. Thermal problems are a global issue, so we would like to make a big push overseas as well.

Our company has graduates from Nagoya University who have studied materials, including those from the Ujihara Laboratory, and recruiting through job sites is also strong. There are few materials-related start-ups, so it seems that those who want to challenge themselves in such companies are attracting a lot of attention.

Women who are raising children are particularly active. Many of them have built their careers at major auto parts manufacturers and other companies, then left when they had children, and they have surprisingly high skills and abilities. We want more of such people to come to our company, so we have introduced a flexible work schedule and other measures to enable them to work in a way that allows them to have a good work-life balance. We also promote the use of childcare leave for male employees, and they take about one month.

In the early days, I was particularly interested in patent-related advice. I didn't know much about intellectual property, so it was very helpful that I was given basic information about periodic patent searches and the need for patent attorneys. I am grateful that the capitalist does not end with the investment, but accompanies me throughout the process and gives me accurate advice each time.

The problem of heat is becoming more and more serious worldwide, including in electronics, and we want to commit ourselves there more and more. We will build up our existing business firmly to increase profitability and aim for an IPO in 2028.

As a field, I would like to enter the data center market. The number of data centers is increasing all over the world, but the problem is that they consume so much electricity that 40% of the electricity consumed is used to cool the servers. We would like to contribute to energy conservation with our materials. We also have a dream to expand our business to heat utilization and reuse of waste heat in the future.

What I strongly feel these days is that we have come this far with the help of many people. The reason for this is that I feel that people are cooperating with us in taking on challenges such as the heat problem with new technology. Deep tech is getting a lot of attention, but I think that deep issues, what we are trying to solve, are equally important. That is why we must continue to have an attitude of challenging difficult and advanced issues. If those who are thinking of starting their own businesses do not lose their sincere attitude, various people will support them and the probability of realization will increase. I think that is important.

(Interviewed in December 2024. Affiliations, positions, etc. as of the time of the interview)

The famous Moore's Law states that the integration rate of semiconductor integrated circuits will double in 18 (or 24) months. This law, which has supported the development of the IT and semiconductor industries to date, is said to be reaching its limits. The new materials provided by U-MAP are indispensable for advancing Moore's law, U-MAP's new materials provide a breakthrough thermal solution that is essential to advancing Moore's Law. We will continue to support U-MAP for further growth.

Masayoshi Ohbayashi

U-MAP Co., Ltd. Website

Please feel free to contact us if you have any questions or concerns.

Inquiry Form